When lubrication is required for high temperatures or high vacuum conditions the liquid lubricants are unsuitable. In such cases dry lubricants are useful. Dry lubricants help to reduce the friction and the wear between the moving parts by eliminating direct contact between them. Dry lubricant can be used for lubrication even in severe conditions.

When liquid lubricants are used in applications that require high temperatures they begin to deteriorate due to thermal instability and this results in degradation of the lubricant. As the temperature rises the reaction rate in the liquid lubricant rises which results in the breakage of chains in the molecules. This leads to polymerisation and sludge formation which affects the lubricating capability. To overcome this dry lubricants are used in such applications.

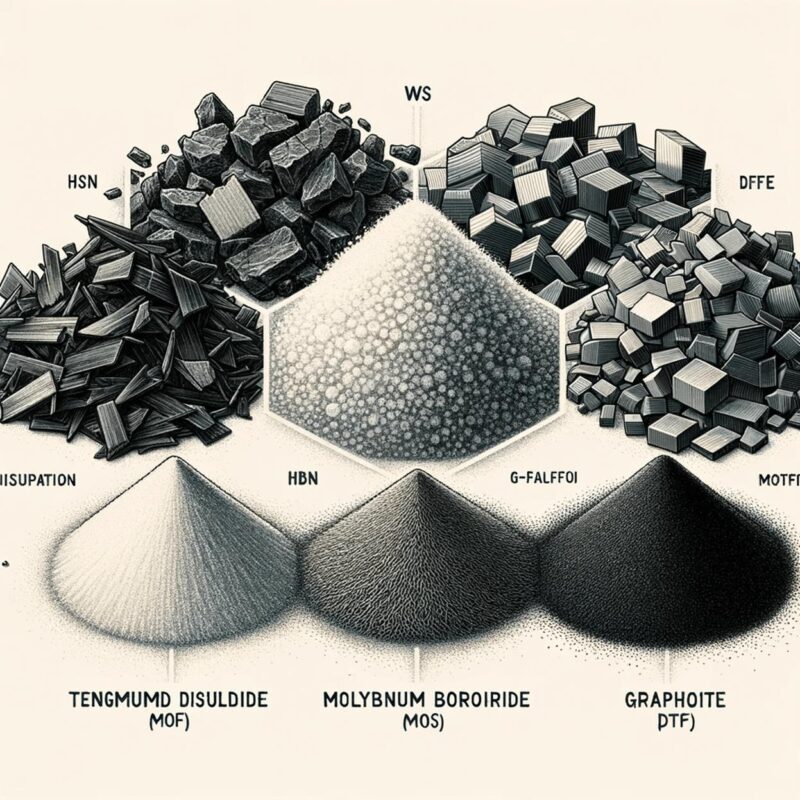

The dry granular powder can work to efficiently lubricate the moving parts in extreme operating conditions. The different dry lubricant powders are tungsten disulfide (WS2), hexagonal boron nitride (hBN), molybdenum disulfide (MoS2), PTFE (polytetrafluoroethylene), and Graphite.

Dry lubricants in powder form can be used in anti-friction coatings. The powders are mixed with a binder and applied to a surface. The powder sticks to the metal surface and forms a solid film. Dry lubricants are also used in composites to enhance the lubricating properties.

Types of dry lubricants

Tungsten Disulfide

It is the most lubricious substance known but due to its high cost, it is used for lubricating some bearings. It can provide lubricity which is unmatched by any other substance. It can be used for lubrication under high-temperature and high-pressure conditions.

It has a layered structure with the S-W-S atoms bonded with strong covalent bonds and the layers held together by weak Van der Waal forces. The layers get sheared easily which results in a low coefficient of friction. It is stable at temperatures even above 550° C.

Hexagonal Boron Nitride

It is also called ‘White Graphite’ and is used in space applications. It is used in applications from metallurgy to cosmetic products.

It has a layered structure with alternating Boorn and Nitride atoms bonded strongly by covalent bonds and layers are held together by weak Van der Waal forces. Its main property is high-temperature resistance up to 1200° C in an oxidising atmosphere. It has a high thermal conductivity.

Molybdenum Disulfide

It is mainly used for lubricating CV joints, space applications, and in vacuum. It occurs naturally as a mineral ore Molybdenite or Jordisite. It has a layered structure with a plane of Molybdenum atoms sandwiched between two planes of Sulphide ions. The layers are bonded by weak Van der Waal forces.

MoS2 is relatively unreactive and does not get affected by dilute acids and oxygen. There is no vapour present in the lattice planes therefore MoS2 can be used in high-vacuum conditions where graphite cannot be used.

The particle size and the film thickness are important factors to consider while using it for lubrication. You should use large particle sizes for rough-cut surfaces rather than for highly finished surfaces. If the particle size is not matched properly then it can lead to excessive wear due to abrasion.

PTFE

It is mainly used as a non-stick coating for cookware. It is hydrophobic and neither water nor water-containing substances can wet it. It is a fluorocarbon solid consisting of Carbon and Fluorine. It is ono-reactive due to the strength of the Carbon and Fluorine bonds. It shows one of the smallest coefficients of friction of any solid.

It is widely used as an additive in lubricating oil and lubricants. It is also used in aerosol lubricating sprays. It has a high melting point and can function well up to 260° C.

Graphite

It is mainly used in railway track joints, air compressors, the food industry, brass valves, bearings, gears, and more. It is used in applications where the use of liquid lubricants can cause the dust particles to worsen the problem.

Graphite is a soft and crystalline form of Carbon and is gray or black in colour. It occurs naturally in metamorphic rocks and exhibits lubricating properties. Its structure is composed of layers of polycyclic carbon atoms that are hexagonal in orientation. The bonds within the layer are strong and the layers are bonded by weak Van der Waal forces. Due to its structure, the layers can easily slide against each other.

Water vapour is an important part of Graphite lubrication. The adsorption of water reduces the bonding energy between the planes than the adhesion energy between substrate and graphite. Therefore, cannot be used for lubrication in a vacuum.